What is Formply? Formply is one of the most important products in modern concrete construction. It is a type of plywood specifically designed to give smooth, clean concrete finishes and withstand the demands of formwork. While its primary use is in commercial and residential building projects, formply can also be used for other applications where a durable, weather-resistant sheet material is needed.

At ATS Building Products, we supply formply across Australia, with large stock holdings in Sydney Melbourne, Brisbane and Adelaide. Our range is designed for both small projects and large-scale commercial work, supported by a wide selection of complementary formwork products.

What Is Formply?

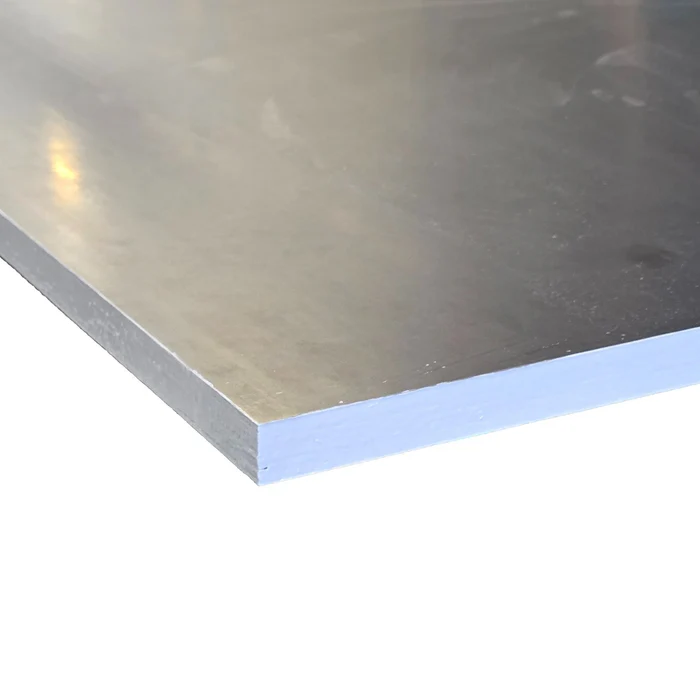

Formply is a structural plywood sheet with a high-quality phenolic resin film bonded to its surface. This film creates a smooth, hard finish that prevents moisture from penetrating the sheet and helps produce clean, even concrete surfaces. The phenolic coating also makes the surface easier to clean and reuse, reducing the cost per pour for formwork jobs.

Formply is usually made from hardwood veneers for strength and stability. The sheets are manufactured to comply with strict industry standards for structural performance, meaning they can be used with confidence in load-bearing applications.

Key Benefits of Formply

1. Smooth Concrete Finishes

The phenolic surface prevents concrete from sticking, allowing for crisp, professional results with less surface preparation.

2. Durability and Reusability

When handled correctly, formply can be reused multiple times for different pours, making it more economical than standard plywood.

3. Weather and Moisture Resistance

The coated surface and bonded layers provide resistance to moisture penetration, helping the sheet maintain its structural integrity in damp conditions.

4. Versatility

While primarily designed for formwork, formply can be used for temporary hoardings, worksite barriers, van linings, benches, and storage shelving.

5. Strength and Stability

The hardwood veneer core gives formply excellent load-bearing capacity and resistance to warping.

Common Applications

Concrete Formwork

Formply is engineered for this purpose. It provides a uniform, non-stick surface that ensures concrete can be poured and stripped efficiently.

Temporary Hoardings

On construction sites, formply sheets can be used for barriers and hoardings that need to withstand weather exposure.

Formply vs Structural Plywood

| Feature | Formply | Structural plywood |

|---|---|---|

| Surface | Smooth phenolic film face | Raw timber face |

| Main use | Concrete formwork and clean finish pours | Structural framing, flooring, bracing |

| Weather resistance | High | Medium |

| Reusability | High with correct handling and storage | Low to medium |

| Finish quality | Produces clean concrete surfaces | Not intended for concrete finish quality |

| Core material | Typically hardwood veneers for strength and stability | Varies by grade, often softwood or mixed veneers |

| Typical cost profile | Higher per sheet, lower cost per pour due to reuse | Lower per sheet for general use |

| Best for | Repeated pours, smooth formwork, hoardings | Framing, subfloors, general structural applications |

The key difference lies in the surface treatment. Structural plywood is designed for load-bearing roles in construction but lacks the film finish required for clean concrete work. Formply combines the structural strength of plywood with a specialist surface designed for the demands of concrete forming.

Why Choose ATS for Formply

When you source your formply from ATS Building Products, you benefit from:

- Large Stock Availability – We maintain consistent supply so you can keep projects moving.

- Competitive Pricing – Quality products at prices that help you stay within budget.

- Product Knowledge – Our team can recommend the right sheet size and thickness for your project.

- Complementary Products – From LVL formwork beams to steel decking, we offer everything you need for a complete formwork system.

Formply is a versatile, high-performance plywood designed to make formwork faster, cleaner, and more cost-effective. Its phenolic-coated surface delivers consistent concrete finishes, while its strength and durability allow for repeated use. Whether you are a builder working on a multi-storey project or a DIY renovator needing a tough sheet material, formply offers the performance and value you need.

At ATS Building Products, we supply a full range of formply and supporting formwork products for projects across Australia. Call our team today for expert advice and competitive pricing on formply for your next job.

FAQs

Formply has a smooth, coated surface designed for concrete formwork, while standard plywood has a raw timber face and is typically used for structural or general-purpose applications.

Yes. The phenolic coating provides weather resistance, making it suitable for outdoor applications, but prolonged exposure without protection may reduce its lifespan.

With proper handling and storage, formply can be reused multiple times for formwork before needing replacement.

Formply is made from multiple layers of hardwood veneer, bonded together and finished with a phenolic resin film for moisture resistance and a smooth surface.